Microtess Delivers Custom Weighing Solution for WaterTreatment Industry

Background of the Cooperation: Alignment of Professionalism and Needs

As a leading innovative enterprise in the weighing technology sector, MicroTess has profound industry experience. Leveraging its extensive expertise accumulated in analog weighing, the company continuously refines the R&D, production, and service capabilities of “high-precision, digital” weighing products. Our automated product portfolio covers diverse application scenarios, including digital/analog weighing sensors, electronic scales, weighing control instruments, explosion-proof electronic scales, and automatic filling machines. These products are sold globally and widely recognized by users, while our technical solutions have served over 20 industries such as chemicals, pharmaceuticals, food, metal processing, and water treatment.

The client in this cooperation is a benchmark service provider in the global industrial and municipal water treatment sector. With over 35 years of experience in membrane treatment technology and integrated desalination system solutions, it operates 8 global operation centers, having led the construction of more than 200 municipal and industrial water treatment projects worldwide. Its business covers core regions including the Americas, Europe, the Middle East, and Africa. Backed by a large multinational group engaged in renewable energy and maritime sectors, the client maintains a leading position in the industry with strong comprehensive strength.

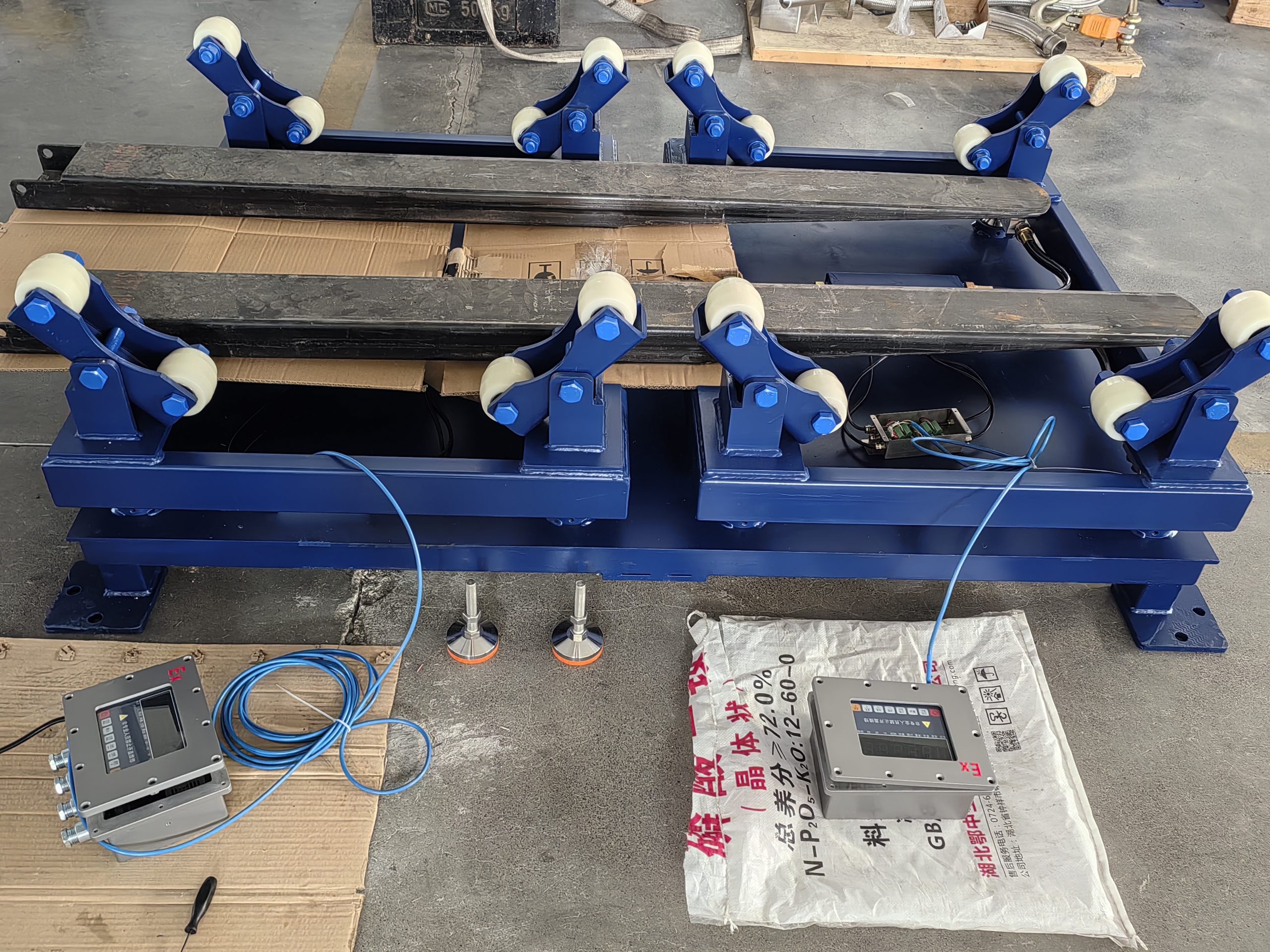

(On-site Diagram of Calibration Test1)

Client Requirements: Dual Challenges of High Adaptability and Strict Standards

- Demand Background: Special Weighing Needs in Water Treatment Scenarios

In the industrial water treatment process, the client requires precise weighing and measurement of ton-level chlorine cylinders to control chemical dosage, ensure treatment efficiency, and guarantee operational safety. Due to the large size, heavy weight of chlorine cylinders, and the harsh requirements for equipment corrosion resistance and stability in the operating environment, conventional standardized weighing equipment cannot meet the adaptability and precision needs. Therefore, a customized Chlorine Ton Cylinder Scale was requested.

- Custom Specifications: Professional Standards Reflected in Details

To match the client’s actual application scenarios, the customized product must strictly comply with the following specifications:

Structure and Dimensions: Overall dimensions of 1700×1100×294mm, including a cylindrical scale body, base frame, and feet, ensuring stable cylinder placement and compatibility with on-site installation space.

Material and Protection: The main structure is made of carbon steel with professional anti-corrosion coating on the surface to withstand humid and corrosive environments and extend equipment service life.

Weighing Performance: Single scale capacity of 5T, equipped with 8 B513 weighing sensors. The sensors are made of alloy steel, comply with OIML R60 standards, have a single capacity of 5T, and are paired with 5-meter-long PVC cables (5.4mm diameter, 4-wire design) to ensure stable signal transmission.

Instrument Configuration: Wall-mounted basic instrument with 2-channel analog output (4-20mA) and 2-channel digital output functions, supporting alarm functionality. The instrument surface requires additional special anti-corrosion treatment to match the overall equipment protection level.

Detail Requirements: The cable length of the scale’s junction box must reach 6 meters to meet on-site wiring needs and ensure convenient installation and use.

(On-site Diagram of Calibration Test2)

MicroTess’s Response: Overcoming Customization Difficulties with Professionalism and Patience

Faced with the client’s refined customization needs, our team fully engaged from design to delivery, advancing the cooperation with the core goal of “precise matching and strict quality control”:

- Repeated Design Polishing: Comprehensive Detail Confirmation

Since the product needed to be fully adapted to the client’s on-site working conditions and cylinder specifications, the engineering team first drafted and optimized the product structure drawing multiple times, focusing on core points such as structural dimensions, sensor installation positions, and anti-corrosion process details. Each design draft was communicated one-on-one with the client via online meetings. For the client’s questions regarding “uniform load-bearing of the scale body,” “safety of cable routing,” and “drilling positions of the base,” real-time online answers were provided and drawing details were adjusted synchronously to ensure complete alignment of product design understanding between both parties and avoid later deviations.

- Multi-Role Collaborative Communication: Ensuring Accurate Demand Implementation

The client’s project team included more than 10 responsible persons from technical engineering, procurement, operation and maintenance, and other departments. To ensure efficient information transmission and no missing requirements, we established a special docking mechanism: assigning a dedicated person to follow up on communications at all stages, regularly summarizing client feedback and synchronizing it to the internal production and technical teams. For cross-departmental questions, multi-party online meetings were organized promptly to clarify details one by one, from process feasibility to delivery cycle, ensuring the orderly progress of the customization process.

(On-site Diagram of Calibration Test3)

- Strict Pre-Delivery Inspection: Quality as the Foundation of Cooperation

After product production, we did not rush to deliver but initiated multiple quality inspection processes:

- First, conduct appearance inspections of the scale structure and integrity of the anti-corrosion coating to ensure no deformation or missing coating.

-

Then, perform full-range tests on the 5T load-bearing capacity using standard weights (error ≤0.1%) to verify whether the weighing precision meets the standards.

-

Finally, test the stability of sensor signal transmission, instrument output functions, and alarm functions to ensure normal performance throughout the process.

Data was recorded for each inspection round, and the product was only confirmed as qualified for shipment when all indicators met the client’s requirements and industry standards.

(On-site Diagram of Calibration Test4)

Cooperation Results: Precise Delivery Gained High Recognition from the Client

After this batch of customized Chlorine Ton Cylinder Scales was delivered to the client’s site and installed and commissioned, their precise weighing performance, adaptive structural design, and reliable anti-corrosion effect fully met the client’s actual needs in the water treatment process, effectively improving chemical metering efficiency and operational safety.

In subsequent feedback, the client stated: “The Microtess team not only accurately understood our customization needs but also delivered products exceeding expectations with professional design capabilities and rigorous quality control. Throughout the cooperation, their patience in repeatedly communicating and confirming details, along with efficient response speed, made us feel the attitude of a reliable partner.”

Case Insight: Customized Services as the Core Capability for Deep Industry Involvement

This cooperation with a high-end water treatment client once again confirms Microtess Technology’s core advantages in the customization of “high-precision, digital” weighing products. We firmly believe that only by deeply understanding the scenario-specific needs of clients in different industries, supported by professional technology, bridged by patient communication, and guaranteed by strict quality control, can we create solutions truly tailored to client needs

In the future, MicroTess will continue to focus on the advancement and innovation of weighing technology, providing more precise and reliable customized weighing products and services for high-end clients in more industries. We aim to help clients maintain a leading position in their respective fields and jointly promote the high-quality development of the industry.